Implantable medical devices (IMDs), from stents to hip replacements, are critical for restoring health and mobility. Traditionally, patients often had to rely on off-the-shelf implants, which don’t always provide the best fit. In other cases, customized IMDs took longer to produce, delaying treatment and prolonging discomfort.

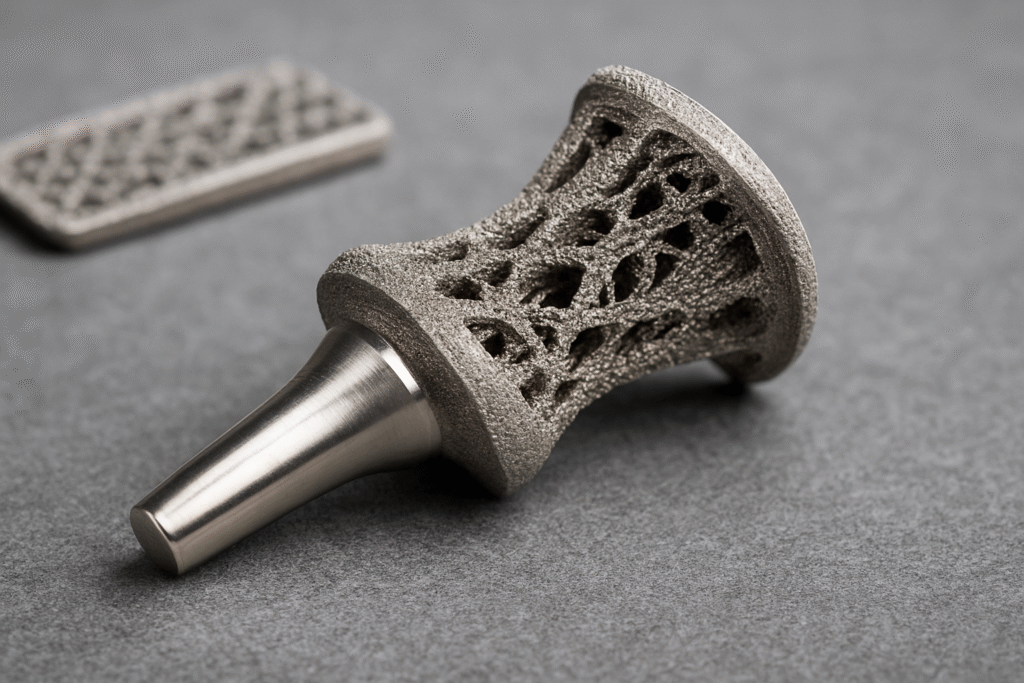

Today, 3D metal printing is reshaping this process. It offers faster production, greater customization, and better biocompatibility, giving healthcare providers and patients more reliable solutions.

Why 3D Metal Printing is a Game-Changer

Unlike conventional methods, 3D printing brings design freedom and supports advanced materials that are difficult to process otherwise. For IMDs, this means implants can be created with:

- Perfect fit and geometry tailored to the patient

- Biocompatible surfaces that integrate naturally with tissue (osseointegration)

- Robust strength to resist biofluids and long-term wear

Compared to plastics or ceramics, metal alloys remain superior for IMDs. Since many implants are already made from metals, 3D printing extends and improves upon existing practices with more flexibility and efficiency.

The Power of Customization in IMDs

Customization is crucial. Poorly fitted implants can cause pain, limit movement, and even require replacement surgeries. With 3D-printed implants, medical professionals can design devices with the exact shape, size, and surface finish needed for each patient.

Common implants now benefiting from 3D printing include:

- Acetabular (hip) cups

- Knee and shoulder implants

- Spinal cages and bone plates

- Stents

- Foot and ankle implants

This flexibility reduces the risk of follow-up surgeries while improving patient comfort and recovery times.

Speed and Efficiency Advantages

Another major benefit of 3D metal printing is speed. Traditional manufacturing often requires additional steps like polishing or hot isostatic pressing (HIP). By contrast, 3D printing can produce finished implants faster, without multiple rounds of post-processing.

Furthermore, healthcare providers can install 3D printers directly in medical facilities, enabling real-time collaboration between clinicians and engineers. This capability speeds up implant design, reduces wait times, and allows quicker patient care.

Expanding Material Possibilities

Beyond speed and customization, 3D printing unlocks new material opportunities. It can work with alloys that are otherwise difficult to process, such as:

- Titanium alloy (Ti-64): Strong, lightweight, and biocompatible

- Cobalt chrome: Highly durable and corrosion-resistant

- Stainless steel: Affordable and versatile

With careful design, scientists can alter porosity, microstructure, and surface finish at the microscopic level. This allows implants to be made either more rigid for strength or more sponge-like for flexibility, depending on their application. For example, spinal cages may be designed to expand with natural breathing movements while still maintaining stability.

Conclusion: A Healthier Future with 3D Printing

3D metal printing is revolutionizing implantable medical devices by combining speed, strength, and personalization. Patients benefit from implants that fit better, last longer, and integrate more naturally with the body. Healthcare providers also gain faster production times and more reliable outcomes, reducing the need for costly and invasive follow-up procedures.

As the technology advances, 3D-printed IMDs will continue to redefine what’s possible in modern medicine—offering patients safer, stronger, and more tailored treatments.