In industrial automation, precision isn’t optional—it’s essential. From controlling high-speed motors to managing energy flow across complex systems, accurate current measurement keeps everything running safely and efficiently. Traditional solutions have done the job for years, but today’s factories demand more. That’s where Allegro’s ACS3704x magnetic current sensors step in, delivering a smarter and safer way to measure current in tough environments.

The Limits of Traditional Current Sensing

For decades, engineers relied on shunt resistors paired with isolation amplifiers. While proven, these setups come with drawbacks:

- Energy loss & heat – High ohmic shunts waste power and generate heat.

- Limited bandwidth – Not ideal for high-frequency applications like motor drives.

- Complex design – Adding galvanic isolation and heat management increases cost and complexity.

As automation pushes for higher efficiency and accuracy, these limitations become bottlenecks.

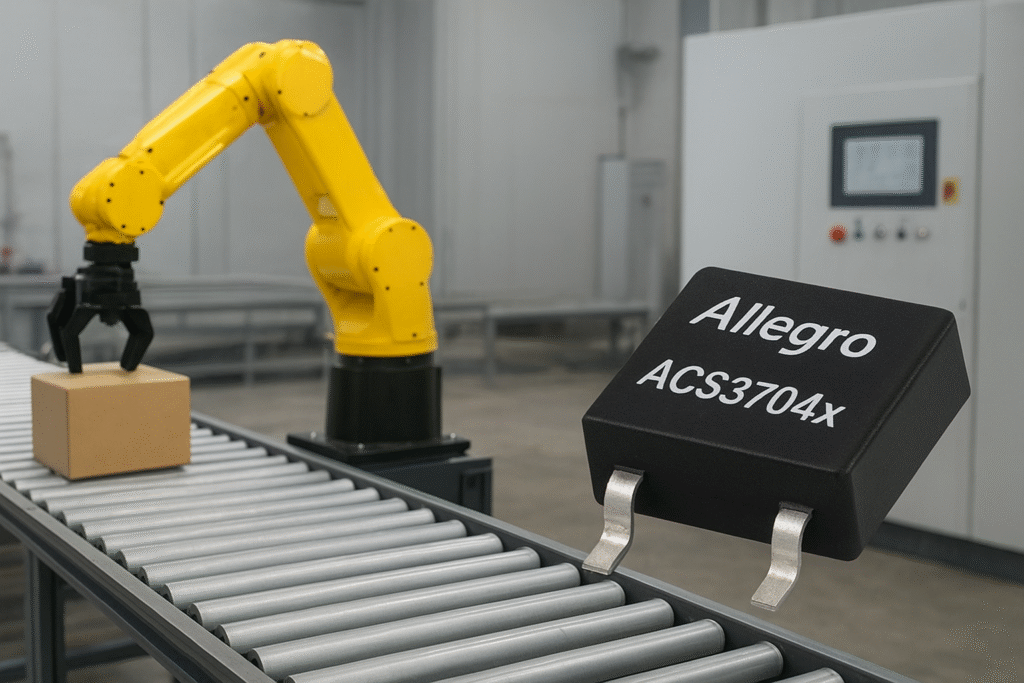

Allegro’s Smarter Current-Sensing Solution: ACS3704x Series

The ACS3704x series from Allegro offers a smarter, more efficient approach to current sensing using advanced Hall-effect technology. Unlike traditional solutions, it can sense the magnetic field around a conductor without breaking the circuit or adding bulky, power-hungry components. This innovative design delivers galvanic isolation for safe separation between high-voltage systems and low-voltage electronics, high-speed performance up to 150 kHz for fast-switching motor drives and power converters, and energy-efficient operation with integrated conductors as low as 1.6 mΩ to minimize power loss. Housed in compact, rugged packages, the ACS3704x series is built to withstand harsh industrial and automotive environments, making it the ideal choice for reliable, precise, and efficient current sensing in modern electronics.

Designed for Modern Engineers

The ACS3704x magnetic current sensors provide analog voltage outputs directly proportional to current, eliminating external shunts. Differential sensing improves immunity to external magnetic noise, while evaluation boards like the Allegro ACSEVB-LH5 Bare and the MIKROE-6632 add-on module make testing easy.

Key specs include:

- Bidirectional sensing up to 30A

- 150kHz analog output for precision in dynamic applications

- Compact SOT23-W package, UL-certified for safety

These features make the ACS3704x a strong fit for motor control, battery management, and high-voltage power supplies.